Defense Distribution Center Wastewater Treatment Plant Design

Design team overcomes site challenges to achieve key sustainability outcomes

Our Client’s Challenge

The Defense Distribution Susquehanna Installation in New Cumberland, Pennsylvania, serves as a primary distribution point for all branches of the U.S. Armed Services and other federal agencies in the eastern U.S.

Covering 851 acres, the installation included a wastewater treatment plant built in the 1960s that provided service to more than 2,000 employees and residents. After 50 years, the plant’s steel tank was at risk of failure, which would discharge raw sewage into the Susquehanna River. Screening mechanisms for incoming wastewater no longer functioned as designed, allowing debris to accumulate inside the aeration and clarification tank. Because of the lack of redundancy, the tank could not be taken offline for maintenance and repair.

Even if it were retrofitted, the plant would not meet Pennsylvania Department of Environmental Protection (DEP) limitations established by Chesapeake Bay Tributary Strategy nutrient reduction discharge limit requirements. Replacing the plant with a technologically advanced facility that could handle 320,000 gallons per day, meet state requirements, and align with the U.S. Army Corps of Engineers’ sustainability goals was of paramount importance.

Gannett Fleming designed the new plant using building information modeling (BIM), helping the team develop accurate cost estimates and demonstrating how the facility would fit on the tight 2-acre site, at and below ground level.

Our Solution

The project began with a planning session involving all stakeholders to define the vision for the new facility and discuss project expectations and challenges.

The team had to fit the new plant into the existing footprint as closely as possible, which includes:

- An influent screening facility.

- Sequencing batch reactors (SBR).

- Aerated sludge holding and post-aeration tanks.

- An ultraviolet channel.

- Three new buildings.

To maintain continuous wastewater treatment at the installation, the team designed a phased demolition and construction sequence featuring multiple temporary bypass systems.

The design of the new facility put the steep site to work, using gravity instead of pumps to move water, minimizing energy use. The team employed an innovative grade-beam and pile-cap system to support the new chemical/blower building, spanning it above two buried 40,000-gallon Imhoff tanks that were discovered during construction. The system allowed the obsolete tanks to stay in place, avoiding the cost of removal and a two-month project delay.

A detailed erosion and sedimentation control plan ensured that construction-related pollution would not enter the nearby river. Delivering the project 150 days ahead of schedule, the team protected the client from DEP fines for failure to meet state discharge limits.

Key Features

- High-strength, small-diameter micropiles securely support structures in poor soil conditions.

- SBR system provides efficient wastewater treatment within a relatively small footprint.

- Influent screening facility eliminates debris accumulation inside the clarification tank, improving system effectiveness.

- Ultraviolet channel provides cost-effective and environmentally safe water disinfection.

- Advanced fire protection and notification system offers protection from incidents related to flammable vapors and combustible dust.

Outcomes

- Heat pump system extracts heat from and rejects heat to treated wastewater effluent, lowering heating and cooling costs for the control building.

- LED lighting system meets industry standards (ASHRAE/IESNA 90.1) for energy-efficient building design.

- Low-flow urinals, occupancy sensors, automatic shutoffs, and integrated thermostatically controlled air intake and exhaust fans reduce energy usage in accordance with client sustainability goals.

- Exterior luminaire design minimizes light pollution, reduces glare, and uses less power than standard lighting.

Awards & Recognition

- Excellence Award, 2018, American Council of Engineering Companies (ACEC) Maryland.

CLIENT

U.S. Army Corps of Engineers, Baltimore District

LOCATION

New Cumberland, Pa.

ROLE

Design

Featured Projects

Transform I-66 Outside the Beltway Project

MTA New York City Transit Environmental Compliance Services

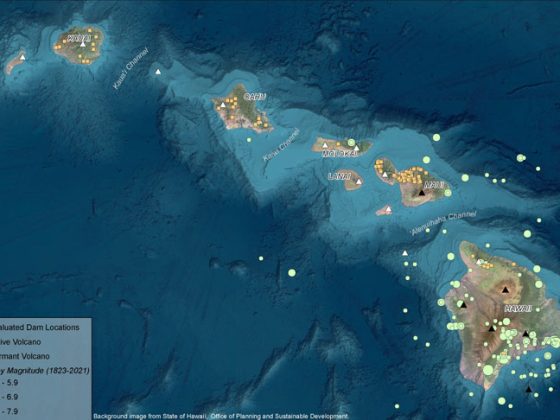

Hawaiian Dam Safety Seismic Hazard Assessment

Route 252 Springton Reservoir Dam Spillway Bridge Improvements